We have the expertise you need to get your custom electronics designed and production-ready. We’ve been in the trenches with some of the most challenging design problems and know what it takes to go from concept to production.

Custom Electronics Design

We have experience designing custom electronics for a wide range of markets including: consumer devices, oil & gas, compute, and aerospace. When working with us, we’ll keep you involved every step of the way and produce a design package that you own. This allows your organization the ability to seamlessly hand off to manufacturing to build your custom design.

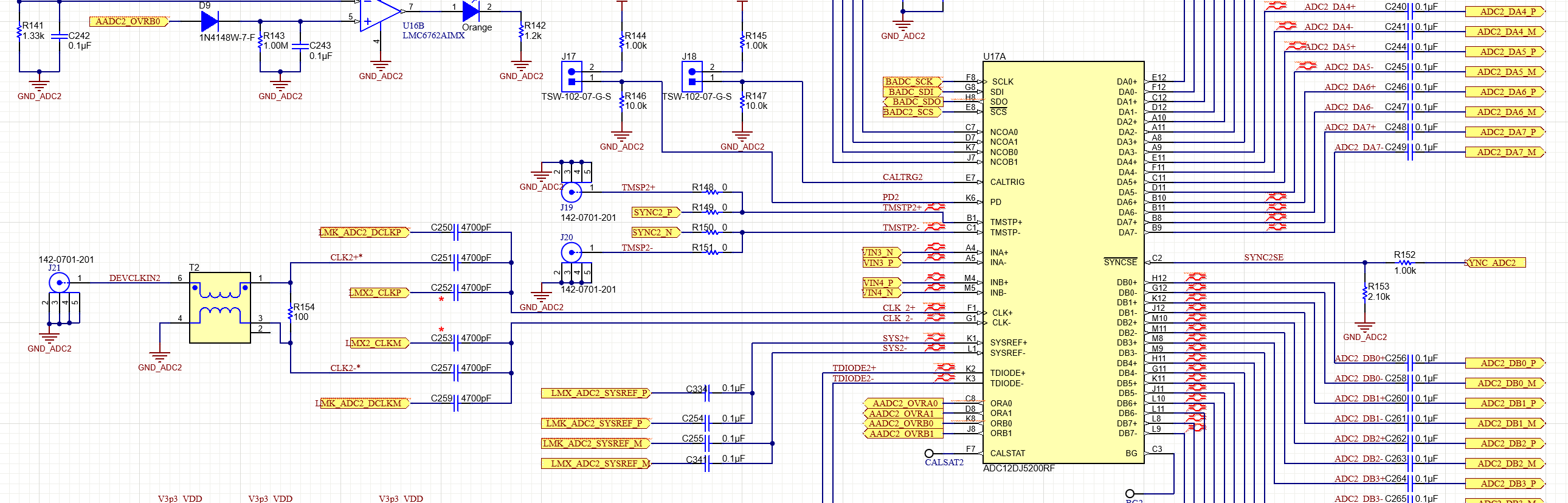

Schematic and PCB Design

- Controlled Impedance Stackup

- HDI Technology (blind, buried, and microvia)

- High-Speed Electronics

- Microcontrollers and FPGAs

- Power Electronics

- Worst-Case Analysis and Design

Comprehensive Design Packages

We provide comprehensive design packages that include all the necessary information for seamless transition from design to production. Our packages include:

- Native Design Files in Altium

- Bill of Materials (BOM) with Alternates and Variants Defined

- PCB Fabrication Drawings (Stackup, IPC Directives, Termination Finish, etc.)

- PCBA Drawings (Component Staking, Depanelization, and Inspection)

- ODB++ and Gerbers

- Production Acceptance Criteria

Design Verification and Validation

A key aspect of electronics design is verifying it meets the intended requirements spelled out during requirements definition. Defining requirements, designing to requirements, and verification against requirements is the process required for proper hardware development and verification.

Design Verification

- Design Review and Hardware Verification

- Requirement Verification Matrices

- Power and Signal Integrity (PI/SI) Analysis

- Design Simulations

EMC Driven Designs

Designing for Electromagnetic Compatibility (EMC) is often a forgotten about aspect of the design cycle. Our designs always prioritize EMC by choosing proper components, designing filters, selecting operating conditions, and following layout best-practices.

Electromagnetic Interference and Compatibility

- Conducted Emissions and Susceptibility

- Radiated Emissions and Susceptibility

- EMC Driven Schematic and Layout Practices